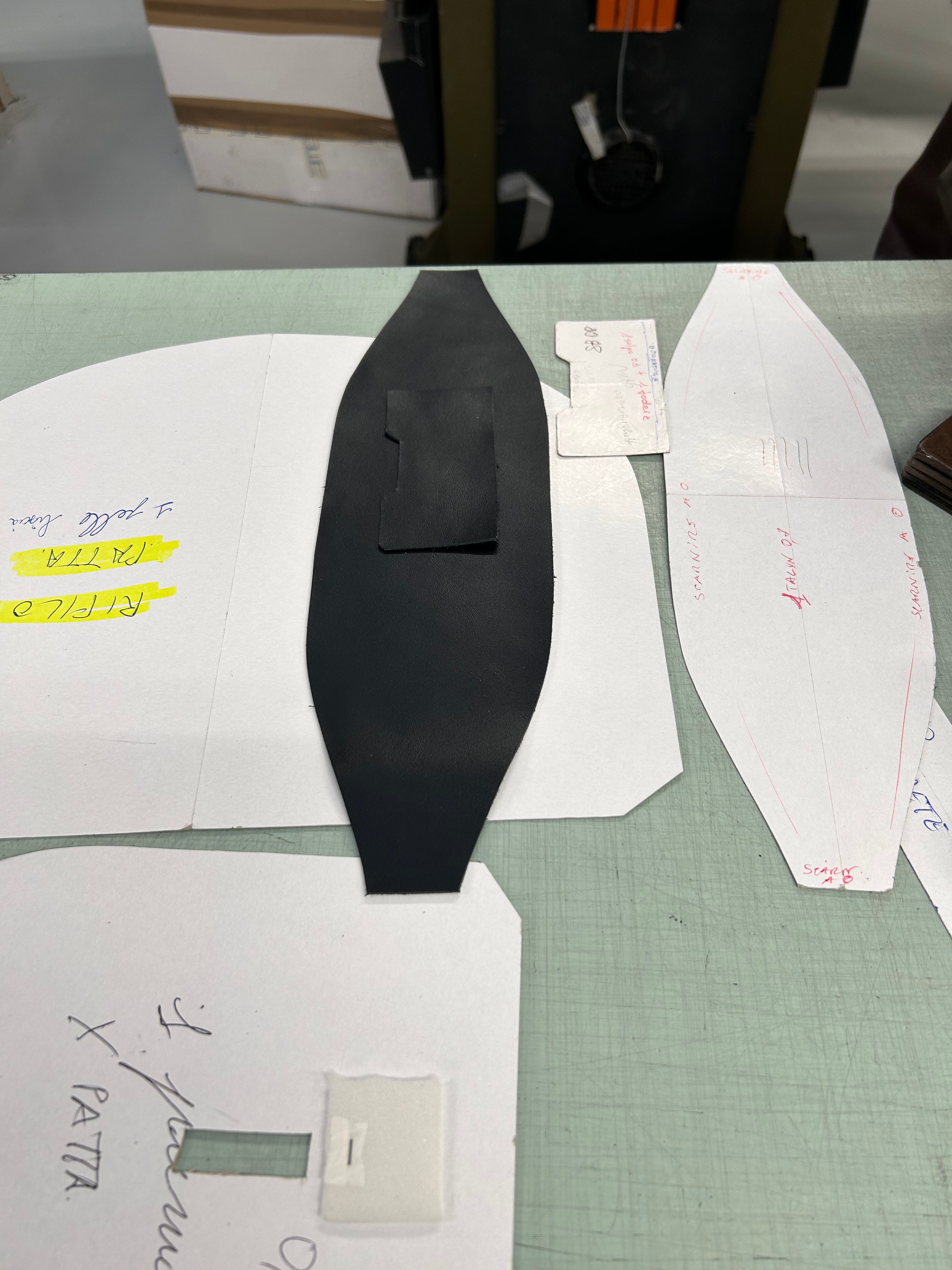

ONE BAG, OVER 30 COMPONENTS

We're honest about our supply chain. While we're committed to European sourcing, we navigate a complex global market. Our priority? Quality, ethics, and your confidence.

LEVEL 1: HANDCRAFTED

HANDBAGS

All our bags are made in Abbruzzo, Italy.

LEVEL 2: COMPONENTS

STUDS, HOOKS, CORDS, CHAINS ETC...

EMILIO-ROMAGNA: Hooks, D-Rings, Studs, Chains, Cords.

MARCHE: Leather, Zipper, Magnets, Sockets.

ABBRUZZO: Lining (Classic Black & Caramel), D-rings.

TUSCANY: Lining (Bordeaux), Leather (Hazel snake & Black Croco), & Rein-force-ment.

LIGURA: Logo Labels.

PIEMONTE: Zipper